There are various applications in multiple industries for dry ice blasting. This unique cleaning solution eliminates the need to use dangerous chemicals and large amounts of water. Maximize your equipment life-span, reduce cleaning costs, and minimize downtime with our dry ice blasting services. See how we can apply our methods to your industry below.

Printing

Buildup of adherents in printing facilities causes machinery to function improperly and can create unsafe working conditions. Dry ice blasting provides a safe, cost-effective, and efficient cleaning solution to keep delays at a minimum.

Automotive

Our non-abrasive technology will remove excess sludge, grease, sealants, and slag from equipment to minimize downtime and keep the assembly line in production.

Manufacturing Plants

Our ice blasting allows manufacturing equipment to be cleaned without disassembly, movement, or cool-down. This is a quick and safe alternative to traditional methods.

Baking & Food Processing

Baking and food manufacturing plants require regular cleaning of wax, proteins, grease, seasonings, crumbs and other build-up. Our cleaning process keeps the equipment operating at peak capacity at an efficient cost.

Electrical Equipment

Dirt, soot, and oil buildup on electrical equipment can cause failure over time, so effective cleaning is required to ensure efficiency of the equipment.

Power Plants

Our dry ice blasting cleaning service removes a variety of adherents from equipment surfaces without destroying any parts. Our service is also environmentally friendly to avoid any fines.

Pet Food Industry

Similar to baking & food processing, pet food processing equipment requires that same routine cleaning in order to be efficient and operate at its peak. Dry ice blasting keeps the equipment clean with minimal downtime.

Historical & Fire Restoration

Historical and fire restoration requires precision cleaning solutions that won't harm the surfaces being cleaned. Dry ice blasting doesn't require damaging water and keeps the original surface from being harmed.

Mold Remediation

Removing mold is a very tedious process that requires advanced cleaning solutions. Dry ice blasting is completely non-toxic, doesn't require any harsh chemicals, and sublimates upon contact to remove the mold entirely. This is also much faster than traditional cleaning methods reducing the risk of further damage from the mold.

Foundries

Removing secondary waste, reducing downtime, minimal cleanup, and enhanced productivity make our cleaning services ideal for operating foundries.

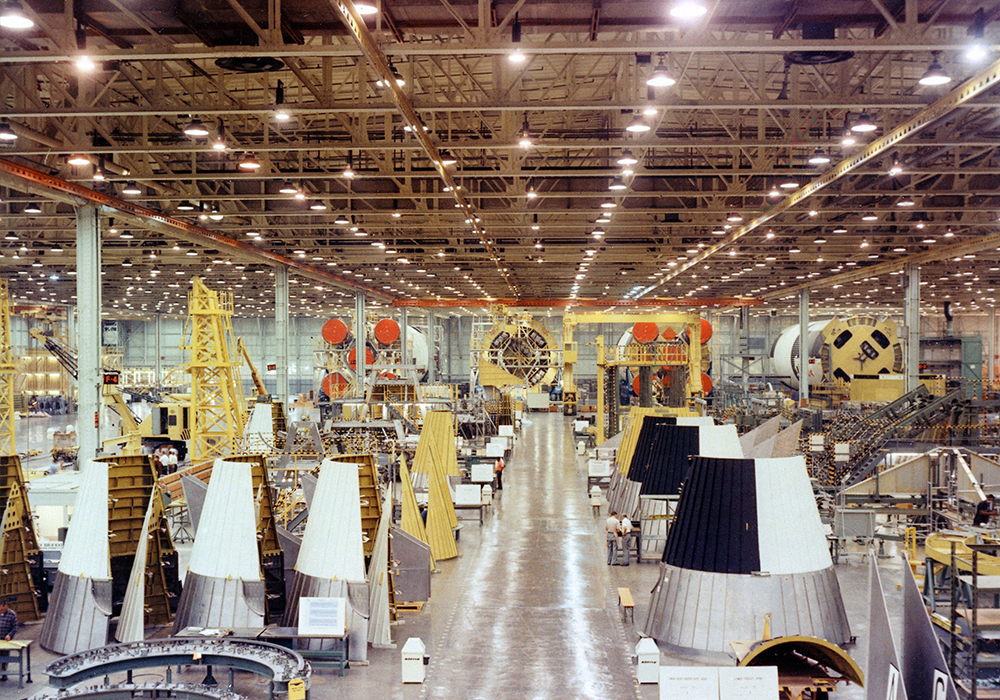

Aircraft & Aerospace

Benefits to our service processes for aircraft and aerospace facilities include a safe working environment while achieving significant cost savings with no waste to cleanup.